News

Easy DIY Projects: How to Build a Plywood Sawhorse

Author Chigwell Building & Joinery

Date 20/12/2016

A simple step-by-step guide to making an adjustable, multifunctional sawhorse

If you're regularly involved in DIY projects, no doubt you've had many scenarios where a sawhorse would have saved you a lot of time and effort. Yet many retail sawhorses can be expensive, impractical and bulky. So what’s the answer?

We have the ideal home project that involves the simple construction of a multi-functional sawhorse using just a single sheet of 8” x 4” 18mm plywood that will do more than just a single job. This design will give you a strong frame to use for cutting long lengths of timber, large sheets of plywood or MDF and act as a sturdy scaffold platform that will take your weight for hard-to-reach jobs indoors. So let's get started and find out how you can make your own lightweight plywood sawhorse in no time!

Materials

Firstly, you'll need a full 2440 x 1220mm (8” x 4”) sheet of 18mm deep plywood. Unfortunately, MDF is not recommended as it is not strong enough for this particular project.

You'll also need boxes of 1” and 1.25” self-tapping wood screws, a jigsaw (or circular saw), an electric screwdriver (or regular screwdriver) and some good quality wood glue.

Cutting List

Your first task is to cut to shape and size all the components of the main support frames of the horse. Firstly, you'll need to cut a total of 4 side panels labelled (A) on the Figure 2. Each of these panels need to be the exact same size at 762mm tall by 406mm wide at the base and 101.5mm at the top centre point. By cutting them to this size, you should be able to get four from your single sheet of plywood, simply by cutting them alternately with two upright and two upside down, laying side-to-side.

Don't forget cut out a semi-circular shape at the base of each side panel. This will create “feet”, preventing the horse from rocking on uneven surfaces. The cutout doesn't have to be accurate but it's essential to have this to avoid an unstable sawhorse when in use.

Next we move onto the sawhorse worktop. Cut 2 lengths of plywood at 1651mm long by 400mm wide. These will form the table top of the sawhorse and be attached together later on to create a strong, weight bearing surface.

Now we need to cut out the support joists for the sawhorse frames. From the plywood you have left, you should be able to cut out 12 lengths of plywood measuring 406mm long by 102mm wide.

And finally, cut yourself two pieces of plywood at 400mm long by 25mm wide, which we'll attach the your final sawhorse worktop near the end of the build which will act as cleats to hold the top in place, when in use.

The Build

Firstly, create a set of 6 double-lined joists by attaching two together each with wood glue, labelled (C) on Figure 2 and as illustrated on Figure 3. Clamping them together whilst they dry will ensure they set accurately with no movement.

Once your double-lined joists have set, attach them along the centre vertical line of your side panels as marked in Figure 3, 51mm from the top of the side panel and then spaced top edge to top edge 228mm apart vertically. Use your 1.25” wood screws to attach the joist at either end to create your two horse bases, as shown in Figure 3. Once done you should have two sturdy based.

To create the worktop, you can take one of two directions. You can either simple attach the two sheets marked (D) in Figure 2 using a combination of wood glue and 1” screws to make a simple 36mm thick plywood base which will be sufficiently strong enough for basic jobs.

If however, you intend to use the sawhorse for other tasks such as a step scaffold that needs to bear significant weight, you will need to build an integrated subframe to add strength and rigidity to the sawhorse worktop. By following Figure 4, you can build a basic frame from leftover plywood or ideally from a few lengths of rough sawn kiln dried timber lengths at 19mm wide by 38mm in depth.

The subframe is fairly easy to build by cutting two strips to exactly the same length as your worktop at 1651mm and then adding 5 side joists incrementally 406mm apart, cut to 324mm in length. Attach the subframe simply by using 1” screws through the plywood worktop surface and additionally through the base sheet.

By adding the subframe, you significantly increase the overall strength of the worktop and reduce the possibility of bending, warping or even breaking under extreme pressure. If you have the materials at hand to do this, we highly recommend you follow this part of the instructions.

Finally, once your worktop is constructed, attach the two remaining cleats marked (B) on Figure 2 approximately 150mm from either edge. These will act as stops so that your sawhorse remains in place whilst in use.

Now you are ready to assemble and use your sawhorse for various cutting tasks and use any one of the three different set heights of the support joists as your scaffold platforms depending on the requirements of the job.

Finishing

If you want to give your sawhorse the finishing touch, give it a light sand with a thin coarse sandpaper, especially along the cut lines to remove any sharp edges or splinters and then you can either stain it with some good quality wood varnish or paint it with hard wearing exterior wood paint.

Easy DIY Projects: How to Build a Plywood or MDF Step Stool

Author Chigwell Building & Joinery

Date 09/12/2016

A simple step-by-step guide to making a robust and handy step stool

No matter how tall you are, there’s always something in the house that’s either out of reach or too high to grab. Accidents in the home are extremely commonplace and falls are amongst the highest incidences that occur. An rickety chair or use of an unstable object can quickly lead to a slip or collapse under your weight and before you know it, you’re being rushed to the emergency room to check for broken bones due to a nasty fall.

Yet the construction of a simple, compact, lightweight and sturdy step stool could be all you need to solve those common problems of reaching objects safely and securely without the risks of doing yourself harm or having to go and grab a bulky step ladder from the garage outside.

Materials

All you need is approximately a 1/4 of a full-sized plywood board or sheet of MDF and you should have enough material to make the stool. Ideally, the thicker the board, the better. We recommend 12mm (1/2”) plywood or MDF minimum, however 18mm is ideal for a studier frame. That way, the finished piece will be stronger and won’t warp or bend under pressure.

To build the step stool, you’ll need a box of 1 - 1.25” self-tapping wood screws, a jigsaw (or circular saw) and an electric screwdriver (or regular screwdriver).

The Build

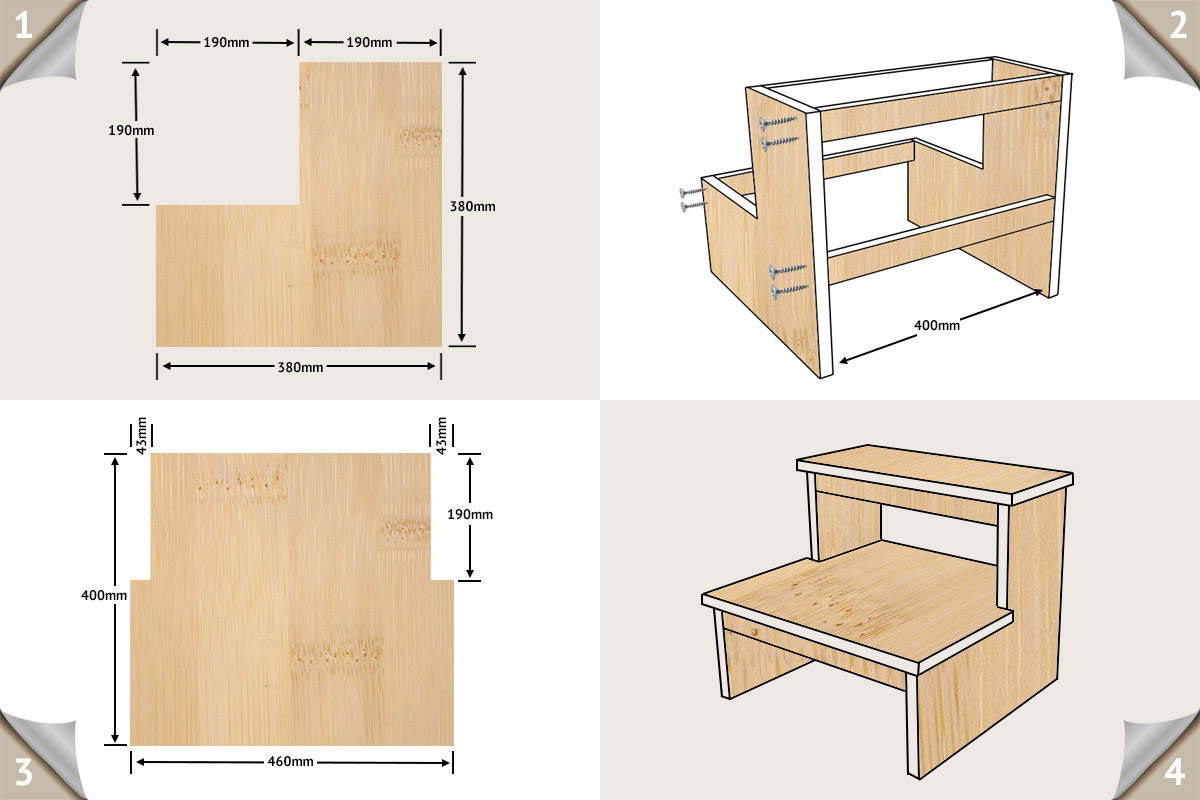

Firstly, you’ll need to cut out two L-shaped sides from a square piece of plywood or MDF that is approximately 380mm (15 inches) in length and depth (see Fig. 1) - the same dimensions both sides and then remove block that is one quarter of the size to create the L-shape. This block should be approximately half the length and depth of your main square piece so should measure 190mm x 190mm (7.5” x 7.5”).

Next, you’ll need to cut four batons of equal length to connect both your L-shaped plywood or MDF panels together which will start to form your frame (see Fig. 2). Each baton should be 400mm (15.75”) in length and 50mm (2”) in depth.

Position the batons as shown in the diagram and attach using a combination of wood glue and two self-tapping wood screws at each end through the sides of the L-shaped pieces. If you are skilled at wood work, you could alternatively, attempt to make jig holes in your batons which will hide screw-heads better and make the finished item look more professional. When done, you should have your basic frame assembled.

Next, cut your top step piece with a jigsaw (or circular saw) at a size of 460mm (18”) in length by 230mm (9”) in depth to allow for plenty of overhang and attach to the top step of your frame using screws through the surface into the batons below (See Fig. 4). If you're feeling confident, you could even cut out a carrying handle shape on the top step to make your stool nice and easy to move and store away.

Finally, we need to cut and attach the bottom sheet to your step-stool. Firstly, cut a piece of plywood sized 400mm (15.75”) in length and 460mm (18”) in width. Now we need to trim the edges halfway to allow for the step to slide and fit snugly inside the frame and then overhang at the front. To do this, you’ll need to cut both edges of your bottom piece 43mm (1.67”) in depth and 190mm (15”) in length to create a fat T-shaped piece (see Fig. 3).

Once cut, the thin edge of your sheet should then slide into the back of the lower step of your frame, allowing you to attach it with screws and wood glue (See Fig. 4). Congratulations, you should now have a finished step stool!

Finishing

If you want to give your step stool a quality finish, give it a light sand with a thin coarse sandpaper, especially along the cut lines to remove any sharp edges or splinters and then you can either stain it with some good quality wood varnish or paint it with furniture paint.