News

What’s the Difference Between MDF & Particle Board?

Author Chigwell Building & Joinery

Date 15/09/2017

Understanding these popular wood products and their practical uses

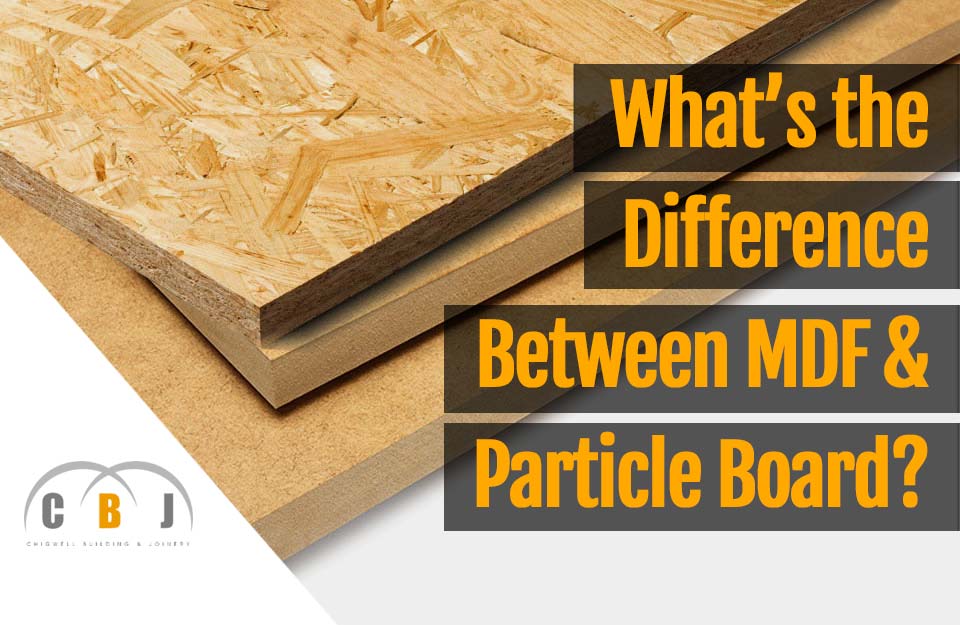

To the unwitting public, many do not realise the fundamental differences between particle board and medium density fibreboard, with many believing they are one and the same thing. This is not the case.

Particleboard is a relatively cheap product which is composed of wasted wood chipping which are compressed and bound using a compound of resins and sawdust along with a lot of heat and pressure. MDF, a more denser product, tends to be more expensive is composed of tiny wooden fibres as opposed to dust but it again, combined using resins and pressurised heat.

In most cases, furniture that is made from MDF is considered to be superior in quality and strength compared to particle board.

What is Particleboard?

Particleboard tends to be used on jobs that do not require a high end durable material and can be commonly found in cheaper furniture products, as well as used in building projects such as flooring substrates and underlays, panelling on fibreglass roofs and temporary partitioning. It’s considered to be a throw away material that has good temporary uses on building projects but seldom is applied for too many permanent structures.

It’s a fairly easy material to work with in terms of cutting and milling but due to it’s structure, tends to tear or chip frequently as pieces of wood chipping start to break away under pressure. Rarely does particleboard get used as a visually exposed face as it is not a great looking product and will often be veneered with a thin laminate to make it appear much more higher end.

It is best used flat as when put under any pressure such as bending or moulding, it breaks, snaps and tears easily.

What is Medium Density Fibreboard?

MDF as it is more commonly known, can be found is many mass produced furniture pieces such as cabinets, shelving and even kitchen units and doors. It’s a strong material that is far easier to mill than particleboard because it is les prone to chipping and tearing. It can be shaped and moulded to a degree and tends to work well for projects requiring routing complicated and elaborate shapes.

Much like particleboard, MDF does tend to be veneered with a laminate on furniture pieces as the material isn’t aesthetically pleasing to look at, so veneers give it a high end finish. it also tends to take to being painted far better than particleboard as well as being far stronger under pressure. It is however not a great material to be used in damp conditions and like particleboard, will deteriorate fast is exposed to moisture of water for too long.