News

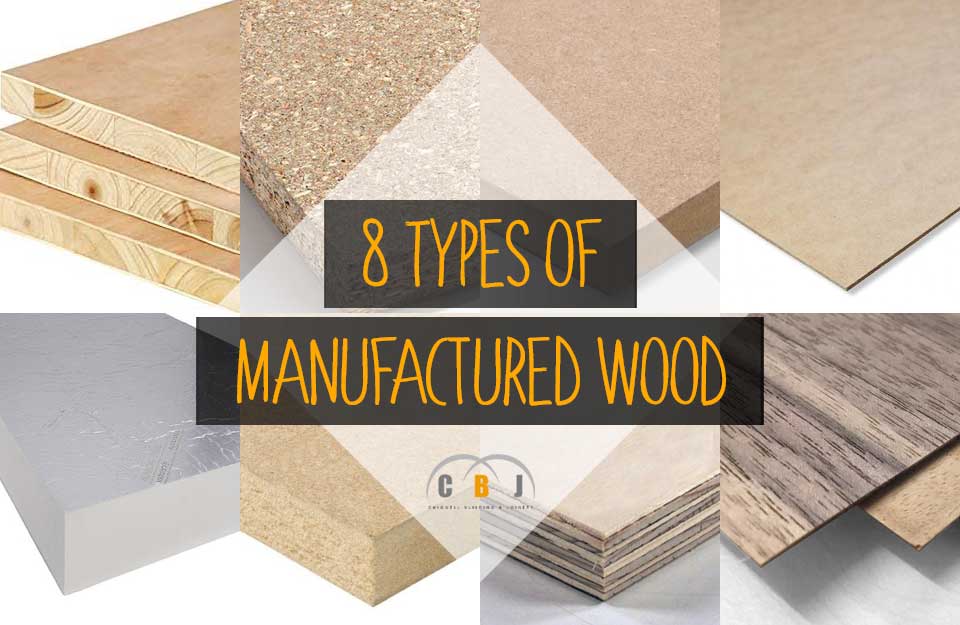

8 Types of Manufactured Wood

Author Chigwell Building & Joinery

Date 01/12/2023

Wood has been a foundational material for centuries, shaping our homes, furniture, and countless other items.

But there's more to wood than what grows in forests.

Manufactured wood, also known as engineered wood, brings forth a world of possibilities.

In this article, we'll explore eight common types of manufactured wood, delving into their uses, advantages and drawbacks.

Table of Contents

- What is Manufactured Wood?

- 1. Blockboard

- 2. Chipboard (Particleboard)

- 3. Fibreboard

- 4. Hardboard

- 5. Insulation Board

- 6. MDF

- 7. Plywood

- 8. Veneer

- Conclusion

What is Manufactured Wood?

Manufactured wood stands as a testament to human ingenuity in the realm of woodworking.

Unlike traditional lumber, which is sourced directly from trees, manufactured wood is an amalgamation of wood fibres, particles, or even entire logs that have undergone meticulous engineering processes.

The production of manufactured wood involves breaking down raw wood materials into smaller components, often in the form of fibres, chips, or sawmill shavings.

These components are then combined using high-quality adhesives, creating a strong bond that is further reinforced through heat and pressure.

This process, often termed as composite technology, results in the formation of sturdy and versatile wood products.

One of the defining features of manufactured wood lies in its consistency.

Unlike natural wood, which can vary significantly in terms of density, texture, and appearance, engineered wood products offer uniformity.

This consistency allows manufacturers and builders to predict and control the material's properties, ensuring that it meets specific standards and requirements.

Moreover, the adaptability of manufactured wood is noteworthy.

By altering the composition, density, and adhesives used in the manufacturing process, engineers and designers can tailor these materials for a wide array of purposes.

This adaptability has led to the creation of diverse engineered wood products, each optimised for particular applications in the construction, furniture, and interior design industries.

Manufactured wood is not merely a replication of natural wood; it represents an enhancement, an evolution that addresses the limitations of traditional lumber.

While solid wood can be susceptible to warping, cracking, and insect infestations, engineered wood products are engineered to resist these issues.

Additionally, due to their consistent quality and availability, they are often more cost-effective, making them an attractive choice for both large-scale construction projects and intricate furniture designs.

1. Blockboard

Image credit: Gharpedia

Blockboard, a versatile type of manufactured wood, is known for its remarkable strength and stability.

The manufacturing process of blockboard begins with selecting high-quality softwood strips.

These strips are carefully arranged side by side and bonded together using strong adhesive.

Once the core is formed, it is enveloped by thin layers of hardwood veneers.

These veneers are glued onto both sides of the core, creating a sandwich-like structure.

The entire assembly is subjected to high pressure and heat, ensuring a secure bond and structural integrity.

Uses of Blockboard

Blockboard finds widespread use in the construction industry, particularly in creating heavy-duty furniture, doors, and panels.

Its robust nature makes it ideal for applications where strength and stability are paramount.

Furniture crafted from blockboard includes cabinets, tables, wardrobes, and shelving units.

It is also frequently employed in interior and exterior doors due to its resistance to warping.

In addition, blockboard is used in wall panels and partitions, where durability and longevity are essential.

Advantages of Blockboard

Exceptional Strength

The core made of softwood strips and hardwood veneers gives blockboard exceptional strength, making it suitable for heavy-duty applications.

Stability

Blockboard is highly stable and resistant to warping, ensuring that furniture and doors retain their shape and functionality over time.

Versatility

Its versatile nature allows for various finishes, making it adaptable to different interior and exterior design styles.

Ease of Workability

Blockboard is relatively easy to cut, shape, and finish, making it convenient for carpenters and craftsmen to work with.

Drawbacks of Blockboard

Weight

Due to its dense structure, blockboard can be heavy, which might pose challenges during installation, especially for larger furniture pieces.

Moisture Sensitivity

While blockboard is more stable than solid wood, it can still be affected by moisture.

Prolonged exposure to damp conditions can lead to damage, making proper sealing and finishing crucial.

2. Chipboard (Particleboard)

Image credit: Wikipedia

Chipboard, often referred to as particleboard, is engineered from a blend of wood chips, sawmill shavings, and resin binders.

These raw materials are mixed thoroughly and then compressed under high pressure and heat.

The heat activates the resin, creating a strong bond that holds the wood particles together.

This process results in a dense and robust sheet material, ready for various applications.

Uses of Chipboard

Particleboard is a versatile material extensively used in furniture manufacturing.

It serves as the core material for cabinets, shelves, tables, and various other pieces.

Its smooth surface and ability to hold finishes well make it suitable for laminating or veneering, enabling a wide range of decorative options.

Additionally, particleboard is employed in interior construction for applications such as wall panels and partitions.

Advantages of Chipboard

Affordability

Particleboard is considerably more budget-friendly than solid wood, making it an economical choice for furniture and interior construction.

Versatility

Its smooth surface allows for easy finishing, enabling a variety of decorative treatments such as painting, veneering, or laminating.

Environmentally Friendly

Particleboard is often made from recycled wood materials, contributing to sustainable practices in the woodworking industry.

Consistency

The manufacturing process ensures uniformity, providing consistent quality and thickness across sheets.

Drawbacks of Chipboard

Moisture Sensitivity

Particleboard is highly susceptible to moisture.

Prolonged exposure can cause swelling and warping, limiting its use in damp environments.

Strength

While sturdy, particleboard is not as strong as solid wood, making it less suitable for applications requiring significant weight-bearing capacities.

Durability

Over time, especially with heavy use, particleboard may chip or dent more easily than solid wood, impacting its long-term durability.

3. Fibreboard

Image credit: Wikipedia

Fibreboard is crafted from wood fibres, usually sourced from recycled wood products or wood chips.

These fibres are mixed with heat and adhesive, then subjected to high pressure, forming a dense and uniform sheet material.

The heat activates the adhesive, bonding the fibres tightly together.

The density of the board can be varied based on the application requirements, resulting in different types such as high-density fibreboard (HDF) and low-density fibreboard (LDF).

Uses of Fibreboard

Fibreboard finds extensive use in the furniture industry, where its malleability allows intricate designs for items like cabinets, tables, and chairs.

High-density fibreboard (HDF) acts as a sturdy foundation in laminate flooring, offering durability and a smooth surface.

Additionally, it serves as the core material for interior doors and decorative wall panels, effectively holding veneers and laminates.

In crafting and DIY projects, low-density fibreboard (LDF) is preferred due to its lightweight nature and ease of intricate shaping.

Advantages of Fibreboard

Versatility

Fibreboard's ability to hold finishes well makes it a preferred choice for applications where a smooth, even surface is necessary.

Economical

Compared to solid wood, fibreboard is cost-effective, making it a budget-friendly option for furniture and interior elements.

Eco-Friendly

Often made from recycled wood fibres, fibreboard promotes sustainable practices in woodworking.

Ease of Machining

Fibreboard can be easily cut, shaped, and moulded, allowing for intricate designs and creative detailing in furniture and decorative pieces.

Drawbacks of Fibreboard

Moisture Sensitivity

Similar to other engineered wood products, fibreboard is sensitive to moisture. Prolonged exposure can cause swelling and damage the material.

Durability

While suitable for many applications, fibreboard is not as durable as solid wood, especially in high-stress areas.

Limited Load-Bearing Capacity

Due to its composition, fibreboard is not ideal for applications that require substantial weight-bearing capabilities.

4. Hardboard

Image credit: Wikipedia

Hardboard, also known as Masonite, is a versatile engineered wood product created by refining wood fibres into a pulp.

This pulp is then combined with adhesives and compressed under high pressure.

Heat is applied during the pressing process, creating a solid, dense board.

This results in a dense and exceptionally smooth board.

Its robust nature makes it a popular choice in various applications.

Uses of Hardboard

Due to its smooth surface and high strength, hardboard is employed in a range of applications.

It is often used as backing material for cabinets, providing stability and support.

In the construction industry, hardboard finds use as door skins, where its resilience and ease of machining make it a preferred material.

Additionally, it is utilised in decorative wall panelling, adding a sleek finish to interior spaces.

Advantages of Hardboard

Smooth Surface for Finishing

One of hardboard's notable benefits lies in its smooth texture, providing an excellent canvas for painting or veneering applications.

High Density and Strength

Its dense composition imparts significant strength, making hardboard resistant to warping and damage, ensuring durability in various uses.

Lightweight and Easy Handling

Despite its robustness, hardboard is relatively lightweight, making it easy to handle and install, enhancing convenience in construction projects.

Versatility in Machining

Craftsmen and builders favour hardboard due to its versatility in machining, allowing for intricate designs and precise shaping.

Drawbacks of Hardboard

Moisture Susceptibility

One of hardboard's limitations is its vulnerability to moisture.

Prolonged exposure to water can cause it to swell or deteriorate, limiting its application in damp environments.

Lack of Natural Grain Patterns

Unlike solid wood, hardboard lacks the inherent grain patterns.

This absence might be a drawback in applications where the desire is for the natural aesthetic of wood, impacting its use in certain decorative contexts.

5. Insulation Board

Image credit: Ebay

Insulation boards are crafted through compressing wood fibres, creating a dense structure optimised for thermal efficiency.

These fibres, often derived from recycled wood products, are bonded under pressure, forming sturdy panels.

Uses of Insulation Board

Insulation boards are widely used in buildings to enhance energy efficiency.

They serve as a barrier against heat transfer, keeping spaces warm in winter and cool in summer.

Advantages of Insulation Board

Excellent Thermal Insulation

Insulation boards excel in providing thermal insulation, regulating indoor temperatures and reducing energy consumption by minimising heat loss or gain.

Lightweight and Easy Installation

Their lightweight nature makes them convenient to handle and install, speeding up construction processes and lowering labour costs.

Eco-Friendly Option

Many insulation boards are made from recycled wood fibres, making them environmentally friendly choices in construction, aligning with sustainable building practices.

Drawbacks of Insulation Board

Moisture Sensitivity

Insulation boards can be sensitive to moisture.

Prolonged exposure to damp conditions might compromise their insulating properties and structural integrity.

Limited Load-Bearing Capacity

While suitable for insulation and soundproofing, insulation boards typically have limited load-bearing capacity, restricting their use in certain structural applications.

Proper support and framing are crucial when incorporating them into construction projects.

6. MDF

Image credit: Amazon

MDF or Medium Density Fibreboard is a versatile manufactured wood product.

MDF is created by breaking down wood fibres into a pulp, which is then mixed with wax and resin adhesive.

This mixture is compressed and heated to form sturdy sheets of uniform density.

Uses of MDF

MDF's smooth and uniform surface makes it a preferred choice for crafting furniture pieces like tables, chairs, and cabinets.

Its consistent texture allows for intricate designs and detailed woodworking.

In addition, MDF is often used for decorative mouldings and trim work due to its ease of shaping and finishing.

It can mimic the look of solid wood at a fraction of the cost.

MDF also serves as a core material for doors, especially those with intricate designs.

It provides stability and durability, making it suitable for interior and decorative doors.

Advantages of MDF

Uniform Texture

MDF has a consistent texture, ensuring smooth finishes on all sides.

MDF easily accepts many forms of primer for a smoother paint finish.

This uniformity is valuable in applications where a polished appearance is essential.

Versatility

MDF readily absorbs paints, and adheres to veneers and laminates, allowing for a variety of finishes.

This adaptability makes it ideal for creating custom designs in furniture and decorative elements.

Cost-Effectiveness

Compared to solid wood, MDF is a more affordable option for furniture and decorative applications, making it accessible for various budgets.

Drawbacks of MDF

Moisture Vulnerability

MDF is sensitive to moisture.

Prolonged exposure to damp conditions can cause it to swell or lose structural integrity.

Proper sealing and finishing are essential to protect it from moisture.

Limited Structural Strength

While MDF is excellent for decorative and lightweight applications, it lacks the structural strength of solid wood.

It may not be suitable for heavy-load-bearing furniture or structural components without proper reinforcement.

7. Plywood

Image credit: Wikipedia

Plywood is perhaps one of the most well-known engineered woods.

Plywood is manufactured by bonding multiple layers of thin wood veneers, known as plies, together.

Each ply is positioned with its wood grain perpendicular to the adjacent layers.

This cross-graining technique enhances the structural integrity of the material.

The layers are bonded with adhesive under high pressure and heat, creating a robust and durable sheet.

Uses of Plywood

Plywood is a staple in the construction industry.

It is widely used for sheathing, roofing, flooring, and formwork due to its strength and resistance to warping.

Plywood's stability makes it valuable in structural applications.

Plywood also serves as a foundational material for furniture, especially in modern and contemporary designs.

Its versatility allows for intricate cuts and designs, making it ideal for crafting chairs, tables, cabinets, and shelving units.

Plywood is also a popular choice for constructing cabinet boxes.

Its stability ensures that cabinets retain their shape over time, even under the weight of kitchen appliances and utensils.

Advantages of Plywood

Strength and Stability

Plywood's cross-grain construction gives it remarkable strength.

It can withstand heavy loads and resist bending and warping, making it a reliable choice for various applications.

Versatility

Plywood comes in different grades and thicknesses, making it adaptable for diverse projects. It can be easily cut, shaped, and finished to suit specific requirements.

Cost-Effectiveness

Plywood offers a balance between cost and performance. It provides significant strength without the high price tag associated with solid wood.

Drawbacks of Plywood

Vulnerability to Moisture

While exterior-grade plywood is designed to resist moisture, it is not entirely waterproof.

Prolonged exposure to water can lead to delamination and deterioration of the material.

Aesthetics

The visible layered structure of plywood might not suit all aesthetic preferences.

In high-end furniture and architectural applications, solid wood veneers are often preferred for a seamless, natural appearance.

8. Veneer

Image credit: Amazon

Veneer is not a wood type per se, but rather a thin layer of wood sliced or peeled from a log.

Veneer is created by slicing or peeling thin layers from logs or using advanced cutting techniques.

These layers, often just a few millimetres thick, showcase the wood's natural grain patterns and colours.

The veneers are then processed to enhance their durability, flexibility, and appearance.

They can be stained, dyed, or even engineered to achieve specific finishes and colours.

Uses of Veneer

Veneer is widely used in furniture manufacturing.

It provides an opportunity to showcase expensive or exotic wood species without the high cost of solid wood.

Veneered furniture pieces often have a polished and refined appearance.

Many high-quality kitchen cabinet doors are crafted with veneered surfaces.

This application allows for uniformity in appearance and texture across multiple cabinet doors and panels.

Veneer is also often applied to decorative panels, enhancing their visual appeal.

These panels find use in interior decor, wall coverings, and even upscale flooring.

Advantages of Veneer

Cost-Effectiveness

Veneer allows the use of premium wood species without the expense of solid wood.

This cost-effective alternative makes it possible to achieve an elegant look within budget constraints.

Variety

Veneers come in a wide array of wood species, allowing for diverse aesthetic choices.

From the warmth of cherry wood to the elegance of walnut, veneer provides options for various interior design styles.

Flexibility

Veneer can be applied to different surfaces, including curved ones, thanks to its flexibility.

This makes it versatile for a range of applications in furniture and interior design.

Drawbacks of Veneer

Durability

While veneer is durable, it is not as resilient as solid wood.

It can be susceptible to scratches and damage, although high-quality finishes mitigate these risks to a large extent.

Moisture Sensitivity

Veneer, especially natural veneer, can be sensitive to changes in humidity.

Extreme fluctuations can lead to warping or delamination, making it important to maintain stable indoor conditions.

Repair Challenges

Repairing damaged veneer can be challenging.

Unlike solid wood, which can be sanded and refinished multiple times, veneer has limited depth, making it harder to repair deep scratches or dents without replacing the entire veneer sheet.

Conclusion

Manufactured wood opens doors to creativity and sustainability in the world of woodworking.

Each type, from the robust blockboard to the versatile plywood and the insulating wonders of insulation board, brings its unique set of qualities to the table.

Understanding these engineered wood varieties not only broadens our options but also fosters a more eco-friendly approach to woodworking, utilising resources efficiently and reducing waste.

As technology advances, we can expect even more innovative uses for manufactured wood, shaping a greener and more diverse future for woodworking enthusiasts and professionals alike.