Edge Banding Process

Edge banding for panel products and doors adds not only a functional aspect to the door in terms of durability and protection from moisture and surface chipping, but also provides a beneficial aesthetic quality which can often be used to compliment the design of any kitchen or bedroom furniture piece.

We offer two types of edging application methods which are: Standard (EVA Glue) and AirTec (latest Hot Air Technology). Our machine is a high end production machine with CNC controlled tooling and settings.

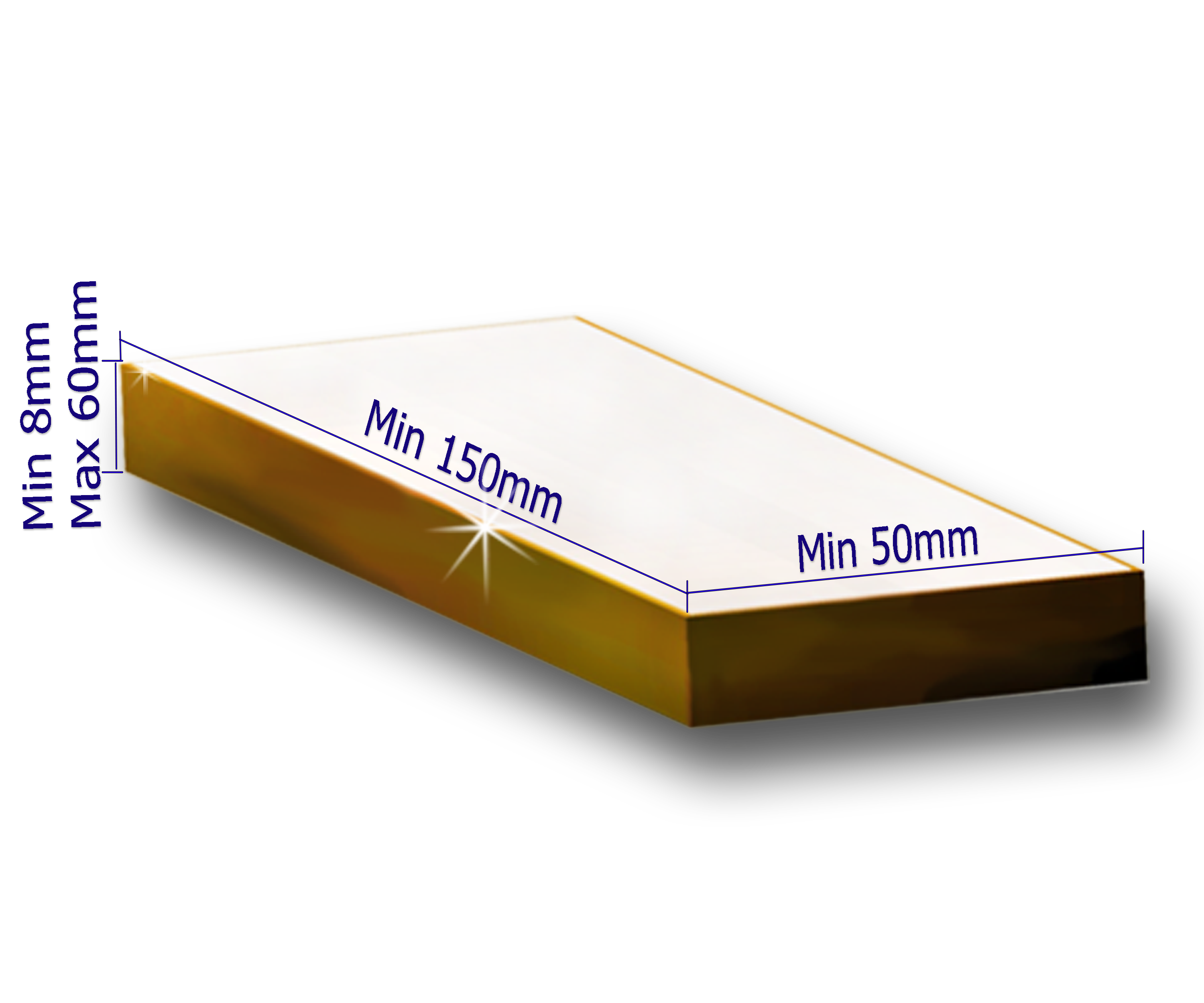

Edge Banding Limitations

Limitations

The machine is limited to what board size can be processed. If the board requires to be edge banded to all 4 edges with corner rounding, minimum part size is 50 x 150mm. 50mm wide material is required in order for the machine to be able to hold the part while it is going through edging process.

Specials

If you require parts that are smaller than our minimum or you are doing various design shapes we have in house manual edge banding facility where we can accommodate your requirements. For special requirement Contact Us via email or give us a call and we will let you know if we can accommodate your needs.

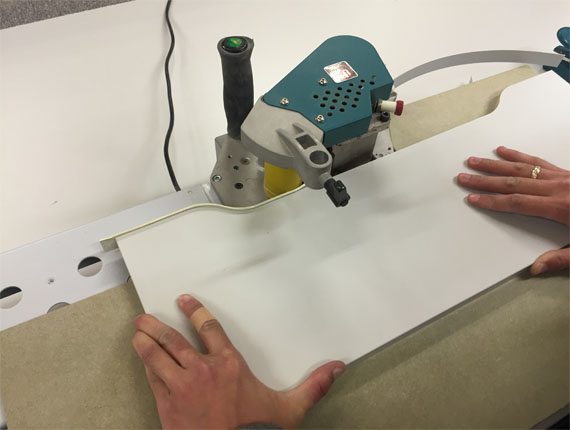

Application Methods

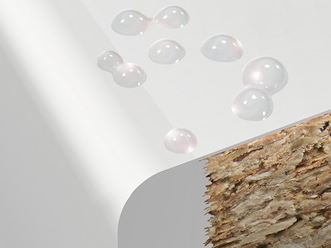

AirTec Application Method

This is the latest trend in edging application technology. AirTec method melts the edging onto the panel allowing to achieve ZERO glue line joint. This method is recommended for areas where the panels are likely to be exposed to moisture or liquids. Zero Glue line joint is not allowing water to penetrate wood based core there for it can not swell. Due to this Technology still being quite new to the market edging choices are limited. Not all our stocked boards have matching AirTec edging. Please see our Board Stock Page where once board is selected available sizes and edging options will be shown prior to proceeding to next step.

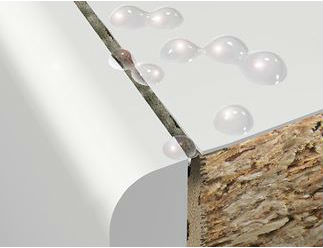

Standard Application Method

Edging material is applied to panel using Hot Melt Glue (EVA glue), although glue layer is very thin it is still visible. Photo shows exaggerated view, normally the gap between the board and the edging is around 0.1mm which is enough for the joint to be seen. This is more noticeable on light coloured panels. This application method is most suited for bedrooms and any other dry area. Kitchen doors and panels in moist areas such as bathrooms not recommended with this type of edging method. As this method has been around for many years, we can match any board in our materials range.

Edging Types and Radiuses

MDF Melamine Tape

MDF Melamine Tape is used on any type of MDF. Melamine edging with impregnated thermosetting resins is designed to seal edges of MDF for ease of decorating. If edging is applied edge finishing is as simple as the surface. Once coating is applied it stops edges from soaking the paint and eliminates necessity of excessive sanding to get the edges smooth. We have a choice of square edged, 0.4mm radius, 1mm Radius and 2mm Radius. Radiuses shown on the photos with explanations below.

Available Radiuses

Edging Thickness: 0.3mm - Radius 0.4mm,1mm,2mm

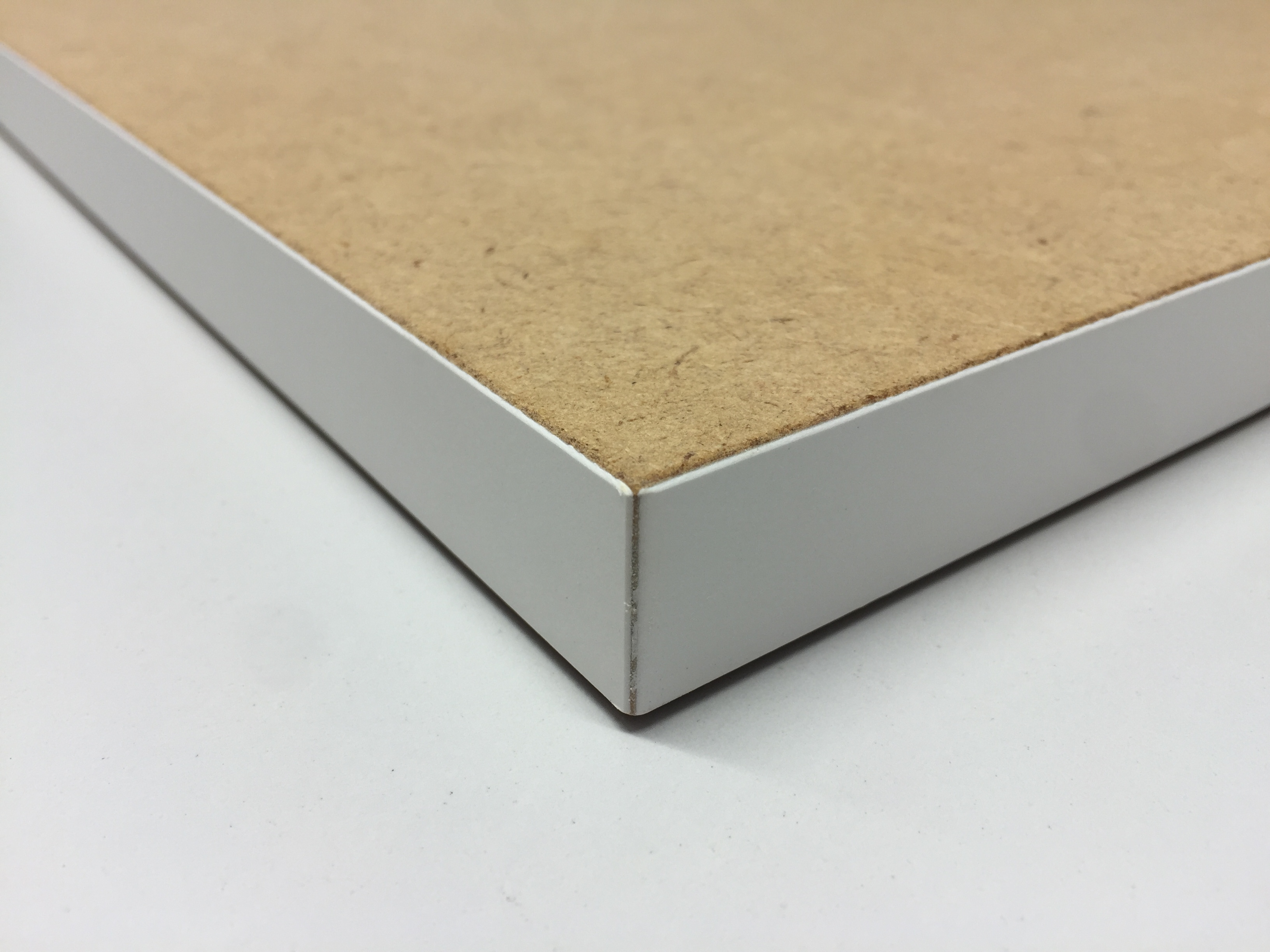

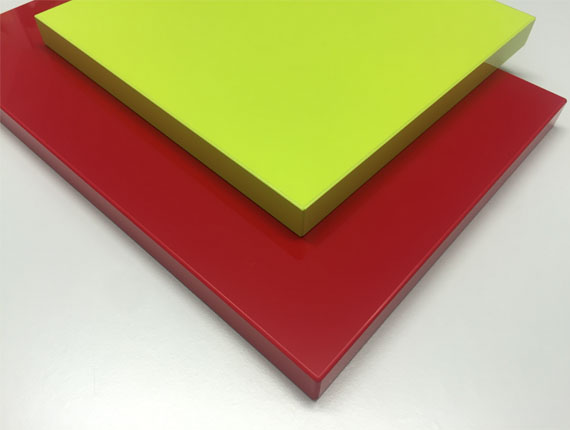

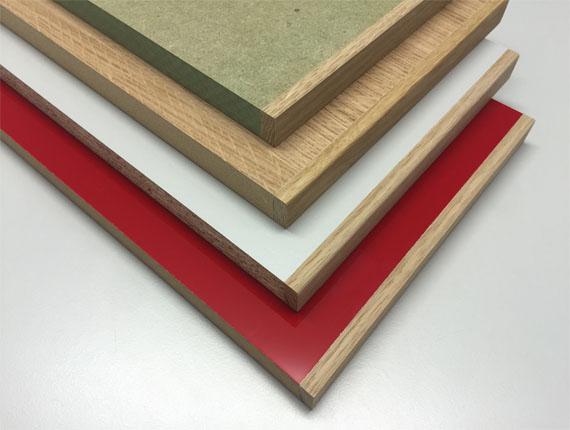

ABS Edging Standard  & Airtech

& Airtech

ABS edging is mainly used for Melamine faced boards where either a matching edging or any other chosen edging is required to seal exposed edges. There is no limitation to imagination of combining various colour edgings and achieving unique designs for any project. Radius can not be bigger than thickness of the edging as this would damage the surface of the board. More options available on special request. Please send us email with your specific requirements.

Available Radiuses

Standard

Edging Thickness: 1mm - Radius 1mm

Edging Thickness: 2mm - Radius 2mm

AirTec

Edging Thickness: 0.8mm - Radius 0.8mm

Edging Thickness: 2mm - Radius 2mm

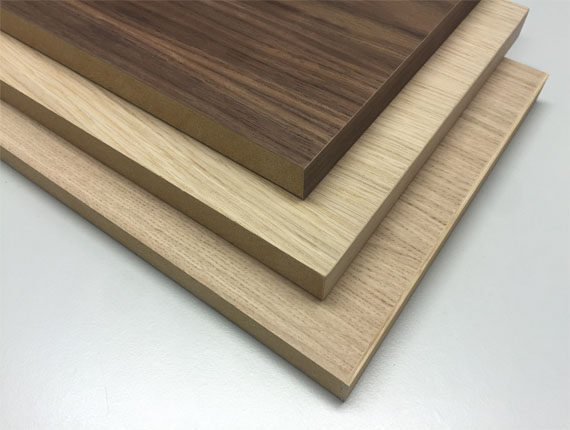

Solid Wood Lipping

We offer solid wood lipping application to Veneered MDF, MR MDF (Moisture Resistant MDF), MDF Standard (Medium Density MDF) and Birch Plywood. In some occasions solid wood lipping is being applied to Melamine faced boards which are to be used for desk tops, shelving, cubicle systems and lots of other applications where a more durable edge protection required or just aesthetic view. We stock most standard species of Solid lipping which are: European oak, American Black Walnut, Steamed Beech, Beech, Maple, Pine, Sapele, Ash and Cherry. These are the most common woods within industry and panel production. Our solid lipping is 8mm thick and has various radius options ranging from 0-2mm radius. MDF with solid wood edging is ideal for veneering or laminates pressing on cut to size material.

Available Radiuses

Edging Thickness: 8mm - Radius 0.4mm, 1mm, 1.6mm, 2mm

Veneered

We offer solid wood lipping application to Veneered MDF, MR MDF (Moisture Resistant MDF), MDF Standard (Medium Density MDF) and Birch Plywood. In some occasions solid wood lipping is being applied to Melamine faced boards which are to be used for desk tops, shelving, cubicle systems and lots of other applications where a more durable edge protection required or just aesthetic view. We stock most standard species of Solid lipping which are: European oak, American Black Walnut, Steamed Beech, Beech, Maple, Pine, Sapele, Ash and Cherry. These are the most common woods within industry and panel production. Our solid lipping is 8mm thick and has various radius options ranging from 0-2mm radius. MDF with solid wood edging is ideal if veneers or laminates are pressed onto boards afterword’s.

Available Radiuses

Edging Thickness: 0.5mm - Radius 0.4mm

Edging Thickness: 1mm - Radius 0.6mm, 1mm

Edging Sides